New UK subsidiary for 3D sand printing to support Aluminium Bronze Casting

Published: 18 November, 2021

LBI Foundries and its subsidiaries LBI, SRI & INOXYDA have announced the launch of their UK subsidiary: LBI Castings.

The company says the creation of the new UK office enables local and increased support of its valued partners by a dedicated sales team.

This new venture expands the team to enable improved customer service and development of existing (nuclear, shipbuilding, power generation and aerospace) customer base in the region.

This office is responsible for the United Kingdom and the Republic of Ireland.

Simon Margison becomes responsible for the new business development activities of LBI Castings for the following plants:

• LBI - Les Bronzes d'Industrie | Centrifugal Casting |

• SRI - Saint-Rémy Industrie | Sand Casting | 2m Sq | components 2 tonnes max

• INOXYDA| Sand Casting | 5m Sq | components 50 tonnes max

Tony Whitehouse Is responsible for the daily activities concerning Inoxyda’s existing customer base.

Bringing 3D Printing for sand-casted aluminium bronze components to the UK & Ireland

3D printing is often referred to as direct part marking; however, other technologies bring new capabilities to sand-casted aluminium bronze components.

3D sand printing consists of printing patterns and cores directly in sand using a process called ‘binder jetting’. It enables direct use of 3D CAD drawings for moulding instead of making up patterns, particularly useful at the prototype stage when designs are not yet finalised or solely require one-off parts (often spare components for old or obsolete equipment).

How does it work?

Inoxyda has successfully implemented this process on several projects by starting with the customer’s 3D CAD model and then:

• adding machining overstock

• including feeders and risers for the mould

• providing a casting simulation (usually with Magmasoft)

• printing the top and bottom mould as well as all the different cores

• mould assembly

An important advantage of 3D sand printing as opposed to direct 3D part marking is the avoidance of costly component replacement and reworking. By keeping the original casting and melting technologies, the same metallurgy, quality, and mechanical properties as pattern-based casted parts are retained with 3D sand printing. This is not the case with direct part marking.

Are all applications compatible?

The main issue, considering today’s technology status, concerns the size of the parts. 3D sand printers are still expensive for large dimensions, yet, as always, solutions exist. For instance, it is possible to print sub-modules of either patterns or cores and then assemble them.

Due to printing speeds but also cost issues, for the moment this technology - which is still at its early stages - is to be used on a case-by-case basis which may mean in combination with conventional sand casting as illustrated in the summary chart below:

A know-how made available for casting projects

3D sand printing casting technology combined with expertise in aluminium bronze alloys help develop complex casted components for pumps, valves and heat exchangers operating in marine environments subject to seawater corrosion.

Case Study: power plant impeller replacement

When a power plant needed to replace a worn-out impeller, on a pump provided in the 1980s for the plant’s cooling system, it was faced with three main challenges:

• Getting the pump back in service in the shortest possible time

• Remanufacturing the impeller without having the original pattern

• Improving the performance of the pump by reviewing the design

Rather than following a more conventional method of replacing the impeller, Inoxyda proposed a new approach to meet the specific challenges faced by the facility in question. It combined the use well known aluminium bronze sand casting with 3D sand printing technology.

The technology

In order to meet the replacement impeller’s requirements, Inoxyda’s expertise in mixing casting and experience with new 3D systems were necessary.

The process of replacing the impeller:

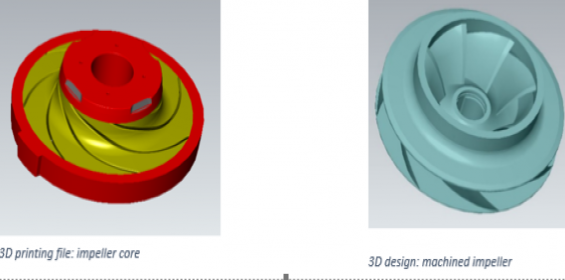

• Scanning the old impeller to create a new 3D file

• Improve the design of the hydraulics

• Use the new 3D file to ‘print’ the sand mould

• Casting

For this project, a large-size printer able to accommodate volumes of 970 X 555 X 460 mm was required. The size of the printer is of great importance, as it limits the size of the components. For larger parts it is, however, always possible to proceed by sub-assemblies to reach the desired volume.

Moulding

Once the 3D files are finished, the next step is sand printing of the various parts of the mould. For this specific project, the mould was created in three parts: the bottom, top and core. If standard casing technology had been used, each part would have needed a separate wooden tooling.

At this point, use of modern 3D printing technology reverts back to the more conventional casting process. Mould assembly needs to be handled by an experienced operator who will carefully position the various components such as coolers, isothermal sleeves and air channels before closing the mould completely.

Completion, machining, and controls

Following completion of the mould, it is filled with liquid aluminium bronze. Once it has cooled, the operators remove the part before cutting the risers and grinding the surface.

As quality is a major requirement for each part of an application, several controls are used, including:

• base material conformity by chemical analysis and tensile testing

• dimensional control

• surface roughness control.

The use of surface roughness control ultimately helps reduce the time spent on the grinding phase.

At this stage, the impeller is ready for final machining, including slotting and balancing. Final controls include dimensional and dye penetrant tests.

Comparison and Limits of 3D Technology

The successful replacement of the impeller for this project provided a unique opportunity for a comparison between standard sand casting and 3D sand printed casting. The use of the two methods together proved to be fully complementary and resulted in reduced lead-time. The primary challenges arose from having a number of trades with different backgrounds working together: design engineers, 3D programmers, moulders, founders/melters, and machining operators were all required to make the project successful. In terms of the quality of the impeller, all of the criteria was reached using the 3D method; surface roughness was even improved.