Valve islands at the double

Published: 07 February, 2020

The fast moving and trend driven nature of today’s industrial markets, mean that OEMs may increasingly need to specify, order and receive parts in double quick time.

Mindful of the fact that delays in engineering can have a significant impact on project schedules, Camozzi Automation says it strives to ensure that its valve components are easy to specify, with straightforward installation and commissioning.

When selecting solenoid control valves for use with compressed air, design engineers may be bombarded with any number of technical questions, ranging from what configuration of valves to employ, to what type would work best. Applications frequently require multiple valves, which is where a valve manifold (aka a valve island) provides the perfect solution.

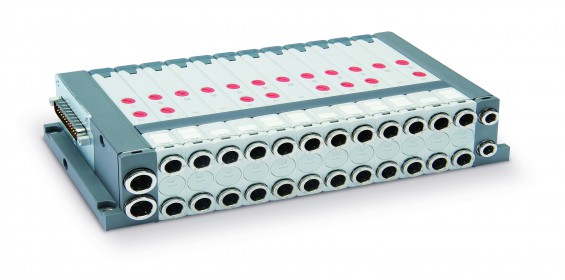

Valve islands offer the ability to connect multiple solenoid valves, each with their own individual coils, together in one component. Streamlined design offers space savings, whilst lower installation costs are achieved since there is no need to wire each individual valve. A reduction in visible wiring also achieves a more aesthetic and compact finish, with the added benefit of a reduction in energy usage.

Camozzi Automation says its extensive UK stock of HN and F Series components gives them the ability to assemble and dispatch bespoke multipole valve islands with maximum speed, meaning that from specification to delivery can often be undertaken in as little as 24 hours, a feat that few other UK suppliers can match.

Customers also have the option to configure their own valve islands using Camozzi’s online configurator, allowing a full part number to be generated, along with 2D or 3D CAD models.